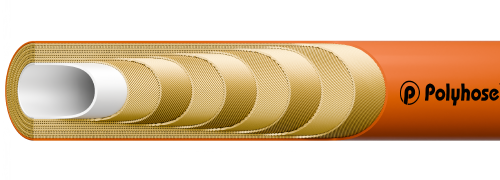

PH908 - 8 SPIRALS OF HIGH TENSILE STEEL WIRE

Construction

Inner tube

Polyoxymethylene (POM)

Reinforcement

- 8 Spirals of high tensile steel wire

Cover

Polyamide (PA)

Application

Water Blast: Heat exchanger tube cleaning, surface preparation(Concrete removal, surface cleaning of buildings, paint removal), tank and vessal cleaning, ultra high pressure waterjet cutting and hydro demolition(cutting and demolition of armoured concrete, pipelines, paper or steel) Hydraulics: Pressure test equipment (valves, tooling and control panels), hydraulic tools (instrumentation packages for gauges, control of service equipment, hydraulic jacks, hydraulic tools) hydroforming Oil and Gas: Gaseousmedia handling

| Item Code |

DN |

ID

|

OD

|

WP

|

BP

|

BR/r

|

W

|

|||

| inch | mm | mm | psi | bar | psi | bar | mm | g/m | ||

| PH908-025 | 4 | 5/32 | 4.0 | 12.8 | 46400 | 3200 | 116000 | 8000 | 175 | 540 |

| PH908-03 | 5 | 3/16 | 4.5 | 15.3 | 46400 | 3200 | 116000 | 8000 | 250 | 700 |

| PH908-04 | 6 | 1/4 | 5.8 | 18.6 | 46400 | 3200 | 116000 | 8000 | 280 | 1100 |

| PH908-05 | 8 | 5/16 | 7.6 | 22.0 | 46400 | 3200 | 107300 | 7400 | 300 | 1500 |

| PH908-08 | 12 | 1/2 | 12.8 | 27.7 | 40600 | 2800 | 87000 | 6000 | 350 | 2100 |

| PH908-10 | 16 | 5/8 | 15.9 | 31.8 | 29000 | 2000 | 72500 | 5000 | 400 | 2600 |

WJTA-IMCA Color Coding Scheme for Pressure Hoses - Maximum Working Pressure Applicable

![]() Temperature Range : Continuous: -30°C to +60°C

Temperature Range : Continuous: -30°C to +60°C